Equipment

Customized for your needs

Hollow fiber module manufacturing equipment

Resin dosing and mixing

Resin dispensing units are necessary for the precise and homogenous mixing of 2K resins components typically used in HF module manufacturing.

Designed for mixing two-component polyurethane, epoxy or silicone resins. Available with various sizes of the tanks allowing adjustment of the device to the scale of the process. Robust design with user-friendly and intuitive software.

Membrane manufacturing equipment

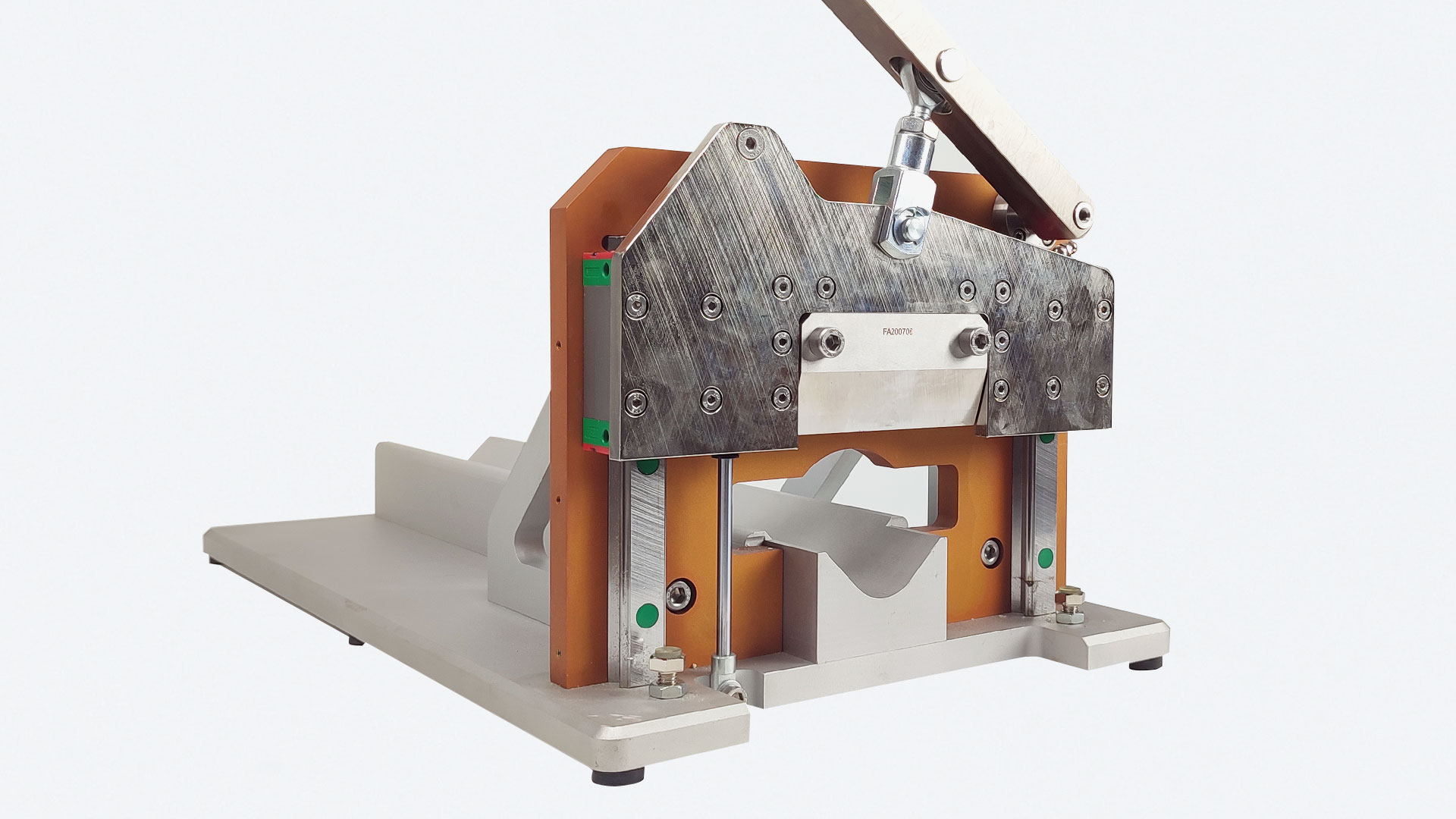

Spinning machines

We deliver spinning machines with cooperation with our business partner – MEMS.

Spinning machines allows manufacturing high quality hollow fiber membranes in controllable and reproducible way.

Available in various scales from prove-of-principle machine, lab scale, pilot to full scale production machines.

Performance evaluation units

Membrane testing units

We offer designing and manufacturing of complete systems for testing membrane performance.

Our lab also carry out tests - identify rejection rate, permeation etc. for various membrane types.

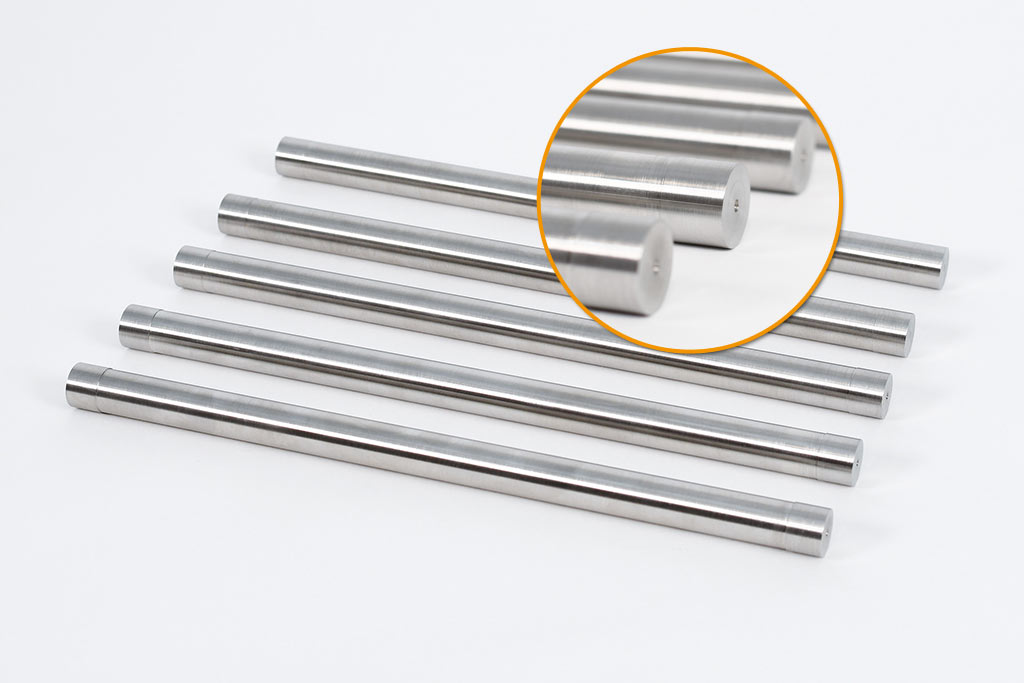

Module integrity testers

Quality control of the manufactured modules requires integrity testing proving effective separation of the feed and permeate side of the membrane.

Filtration pilot plants

Pilot plants allow upscale and optimization of innovative and existing separation solutions in novel application.

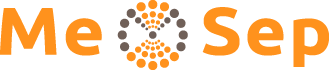

Customized equipment

Made to order (MTO) equipment

Me-Sep can provide customized membrane manufacturing equipment used in manufacturing and testing of flat sheets and hollow fibers membranes from a lab to a full-scale production.

Individual needs

We work close to our customers on development and adjustment of the instruments to individual needs.

Full documentation and training

We always deliver full documentation and training to our clients ensuring smooth operations following equipment commissioning.

After-sales services

We also offer after-sales services with technical support or adaptation of the equipment to a new specification.