We offer the full range of Convergence systems

Me-Sep is the “Awesome Ambassador” and authorized reseller

of the Convergence Industry B.V. equipment

Mini UF - NF - RO bench scale crossflow skid

For quick membrane screening Convergence has a fully automated, entry-level unit.

When in need for a compact and easy to use system for quickly evaluating fluxes of membranes or filters, the Convergence crossflow system PONTOS is the perfect choice.

The system performs cross-flow and dead-end tests from 1.5 up to 60 bar. The system is flexible and can connect Convergence test cells and modules, but also third party test cells and modules.

Via the easy to use touchscreen interface the user can set up pressure step experiments. The system runs automatically and logs the data (pressures, feed flow, permeate weight and flux).

The integrated feed vessel has a cooling/heating option and can also be connected to an external vessel. The automatic pressure controller can run both at low pressure and high pressures, making the system suitable for UF up to RO membrane processes.

SPECIFICATIONS

- Crossflow range: 0 – 1.2 L/min

- Pressure range: 1.5 – 60 bar, automatic pressure control

- Touch screen interface: programmable automatic pressure steps and datalogging

- Connects flat cells and hollow fiber

- Integrated feed tank with heating/cooling capacity

- Flux measurement with integrated balance (6 kg maximum)

- Works with crossflow and dead-end cells

- Fits external feed tanks for larger batch volumes

Custom membrane pilot

On request, Convergence can assist you with designing and constructing your custom fluid-handling device for research or industrial purposes. Convergence supports you from idea generation through basic and detail engineering up to small scale production of your custom product. Our flexibility, reliability and pro-active way of work shines through all our products and ensure high quality and reliability of our systems.

All Convergence Inspectors that you find on this website have their origin in customer requests for custom pilots we have received over the past years. Our knowledge on fluid handling has enabled us to realize those projects and expand our portfolio. So in case the application you are looking for is not present on this website, just get in contact with us. We are confident that together we can work out a solution to your problem. So whether you are in the automotive, membrane, medical, energy or chemical industry: don’t hesitate on contacting us.

SPECIFICATIONS

Your idea, your specifications, our final touch!

Membrane Distillation pilot

The Convergence Inspector Membrane Distillation pilot was developed to evaluate the performance of membrane distillation processes. It is suited for direct contact membrane destillation (DCMD), air gap membrane destillation (AGMD) and vacuum assisted membrane distillation (VAMD). Also standard multifunctional membrane destillation cells can be delivered with the system.

It consists of two circulating loops of fluids, one hot and one cold. Inside a membrane module both streams are in non-wetting contact with the membrane. The temperature difference between both sides induces a partial vapor pressure gradient. The membrane lets certain compounds diffuse which condensate again on the cold side. Two balances placed at both feeds allow the calculation of permeation rates. The system comes with a flat sheet membrane module that can be used in direct contact or air gap method configuration.

The setup comes with isolated tubing that allows both feed streams to be circulated with minimum heat loss. It is also equipped with plate and frame heat exchangers and can be connected to any heating or cooling bath (baths are optionally available).

The user-friendly software interface records flows, temperatures and pressures and allows the creation of individual test scripts. Whether you want to perform permeability tests at several different flow or temperature steps the MD Inspector has you covered. It also allows automatic calculation of permeability, TMP (trans-membrane pressure), temperature gradients and other user defined calculations. The system allows you to attach all kinds of modules and thus makes it extremely flexible.

The system is highly customizeable and can for example include additional sensors, in-line chemical dosing or vacuum assisted permeation for vacuum membrane distillation (VMD) and has many more options available.

Optional

- In-line pH or conductivity measurement

- Customized flat sheet membrane modules

- Customized flow- and pressure range (higher or lower)

- In-line chemical dosing

- Heating and cooling baths

- Vacuum assisted permeation

SPECIFICATIONS

- Feed flow range: 30 – 120 L/h

- Feed flow accuracy: < 1 %

- Pressure range: 0 – 4 bar

- Pressure accuracy: < 0,1 %

- Temperature range: -10 – 70°C (higher temperatures optional)

- Dimensions: 60 x 50 x 93 cm

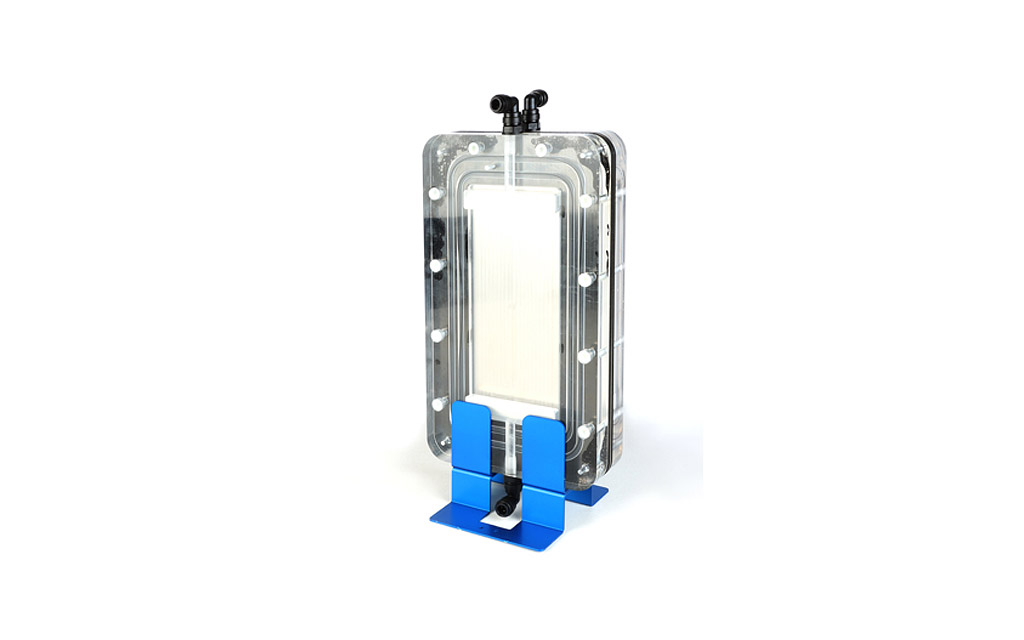

Flat sheet test cell MD/AGMD/DCMD

The flat sheet test cell for MD, AGMD and DCMD work perfectly with our Convergence Inspectors. The test cells are specially designed and optimized for experiments on flat sheet membranes. The cells are multifunctional and can be used for membrane destillation (MD), air gap membrane destillation (AGMD) or direct contact membrane destillation (DCMD). With different layers you can build up the cell the way you need it.

Apart from building Accurate, Automated and Awesome fluid handling systems, Convergence Industry also provides you with the suitable membrane test cell or module to go with your setup.

The cell for MD, AGMD and DCMD work perfectly with our Convergence Inspectors. The test cells are specially designed and optimized for experiments on flat sheet membranes.

We offer standard test cells and modules for flat sheet and hollow fibre membranes in several different sizes and materials like PMMA, PVDF or stainless steel.

SPECIFICATIONS

We offer the following flat sheet test cells in the following sizes and materials:

MD, AGMD and DCMD big

- Membrane size: 110 x 260 mm

- Pressure rating: 10 bar

- Material: PMMA

- Membrane type: flat sheet

MD, AGMD and DCMD small

- Membrane size: 40 x 150 mm

- Pressure rating: 10 bar

- Material: PMMA

- Membrane type: flat sheet

Microbial Desalination Cell pilot

The Microbial Desalination Cell pilot system combines the Microbial Fuel Cell (MFC) and Electrodialysis (ED) process to simultaneously treat wastewater, desalinate saline water and produce electricity.

The MDC consists of three compartments separated by an cation exchange membrane (CEM) and an anion exchange membrane (AEM). The first chamber contains the cathode which is connected to the anode in the third chamber. Seawater solution is flowing in the between the cation ion exchange (CEM) and anion ion exchange (AEM). The waste water solution flows in the third chamber which contains also the anode. The anode is responsible in treating the waste water by organic degradation and producing electricity, where bacteria oxidized the organic matter to carbon monoxide (CO2), hydrogen ion (H+) and releasing free electrons in the anolyte. The electrons flow from the anode to the cathode through an external electrical circuit. Thus electricity is produced and waste water is treated simultaneously. The electrons are reduced by electron acceptor at the cathode, which create a potential difference between anode and cathode. The potential difference drives the transport of ions from the saline water or seawater in the middle chamber and results in desalting seawater.

The performance of MDC will be measured based on the power density produced using a potentionstat connected to the anode and cathode and other equipment. The MDC can be combined with capacitive dionization cell or reverse osmosis membrane or forward osmosis and can work in batch or continuous mode.

The user-friendly software interface records flows, temperatures, conductivity, pH and pressures and allows the creation of individual test scripts. Whether you want to perform tests with several different flux steps or simulate on-field operation with cleaning steps, the MDC Inspector has you covered. It also allows automatic calculation of crossflow velocity, salinity and other user defined calculations. The system allows you to attach all kinds of custom membrane modules and thus makes it extremely flexible.

Optional

- Customized flat sheet membrane modules

- Customized flow- and pressure range (higher or lower)

SPECIFICATIONS

- Feed flow range: 12 – 72 L/h

- Feed flow accuracy: < 1 %

- Pressure accuracy: < 0,1 %

- Conductivity accuracy: 0,33 cm^-1 +- 5%

- pH accuracy: ± pH 0,05

- Dimensions: 60 x 50 x 93 cm

Pervaporation pilot

The Convergence Inspector Pervaporation pilot was developed to perform permeability studies at different temperatures and pressures. The term pervaporation is derived from the two steps of the process: 1) permeation of the permeate through the membrane and 2) its evaporation at the permeate side.

The unit includes a circulating feed and a permeate line. On the permeate a vacuum is applied to increase the driving force of the process. An in-line heat exchanger then condenses the permeate. The pervaporation setup allows the separation of two or more components that are difficult to separate using common thermal separation processes like distillation. It is commonly used for dewatering of hot organic solvent streams.

The user-friendly software interface records flows, temperatures and pressures and allows the creation of individual test scripts. A permeate side balance allows automatic calculation of permeability. The system allows you to attach all kinds membrane modules and thus makes it extremely flexible.

Optional

- In-line pH measurement

- Customized flow- and pressure range (higher or lower)

- Upgrade to chemical resistant Hastelloy/Duplex components

- Heating and cooling baths

- Peltier cooler

- N2 cold trap

- Permeate side flowmeter

- ATEX ZONE II configuration

SPECIFICATIONS

- Feed flow range: up to 325 L/h

- Feed flow accuracy: < 2 %

- Pressure range: 0,5 – 6,9 barg

- Pressure accuracy: < 0,1 %

- Temp. range feed: 0 – 100°C (higher temperatures optional)

- Dimensions: 60 x 50 x 93 cm

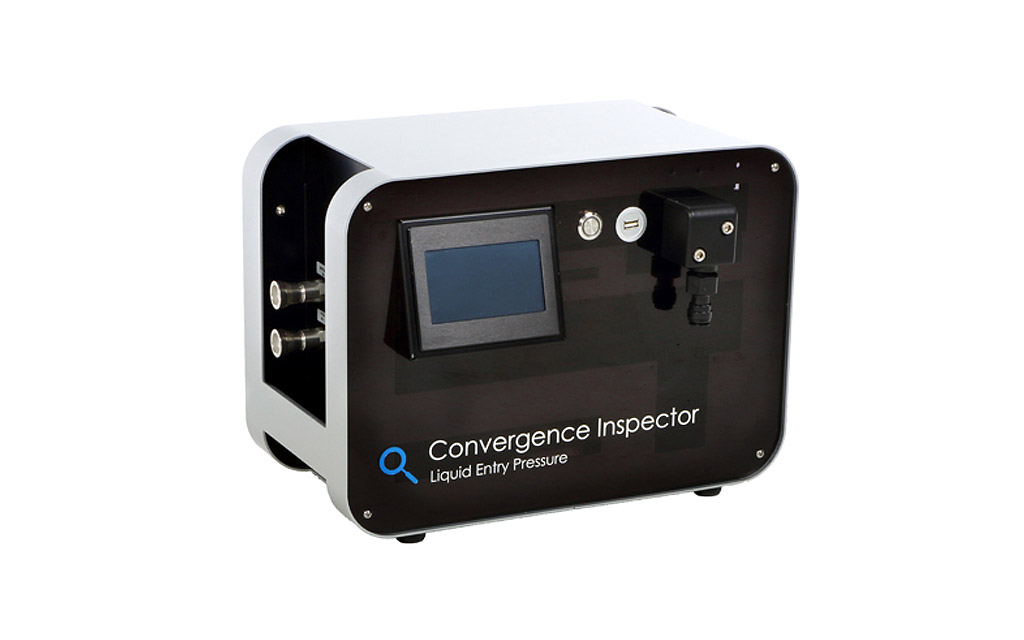

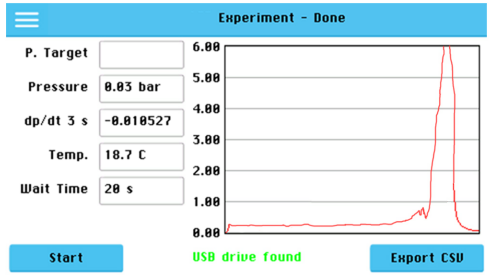

Liquid Entry Pressure tester

The Convergence Liquid Entry Pressure (LEP) tester is essential when characterizing membranes, especially membranes used in Membrane Distillation processes. The system allows a quick, traceable and reliable automated method to characterize those membranes.

Especially in membrane distillation processes it is of utmost importance that wetting of the membrane does not occur. Therefore, the process must be operated at a transmembrane pressure lower than the LEP of the membrane in order to prevent liquid from permeating through the membrane.

The LEP of the tested membrane is determined by applying small pressure increment steps. After each step the pressure decay is measured. If no wetting of the membrane takes place, the pressure decay will be zero. When wetting starts to occur, a pressure decay is observed and the test is stopped. The user can set the incline at which the pressure steps are applied and can perform a zero calibration to increase accuracy. The design of the Convergence LEP tester allows the user to test both hollow fiber and flat sheet membranes. A 25 mm flat sheet disc holder comes with the system. The unit is controlled with the user-friendly software on an embedded touchscreen and data can be exported via USB.

SPECIFICATIONS

- Pressure range: 0,1 – 6 bar

- Pressure accuracy: < 0,1 %

- Dimensions: 40 x 21 x 29 cm

- Diameter filter holder: 25 mm (47 mm on request)

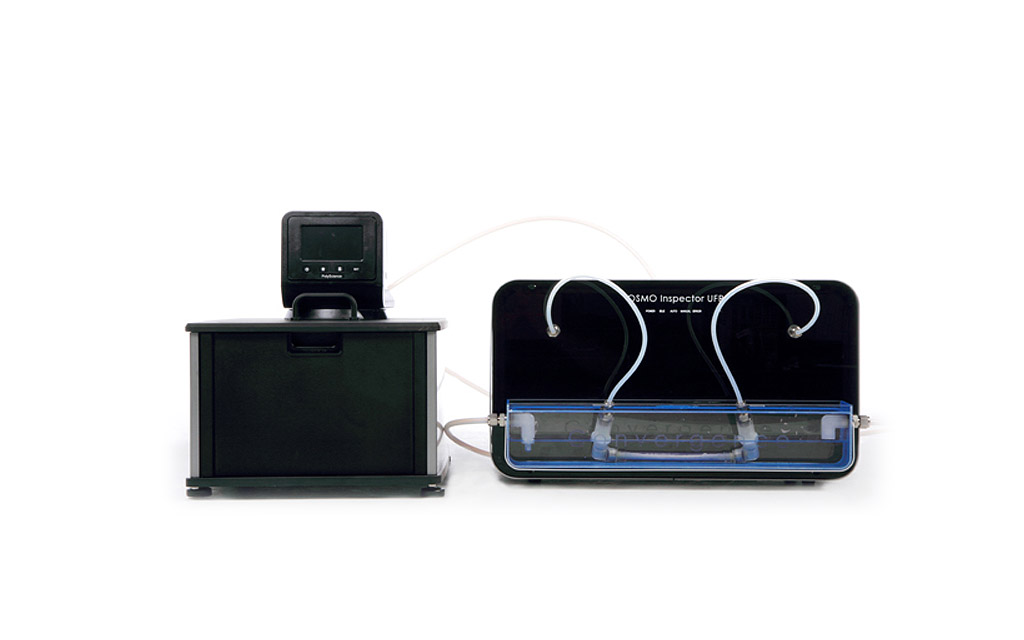

Ultrafiltration rate pilot

The Convergence Ultrafiltration rate and Dialysis Pilot was developed to quickly evaluate the performance and quality of dialysis membranes and processes. The system can work with water, blood plasma or other liquids. The system can perform typical experiments like ultrafiltration rate or measurements of diffusion coefficients and fits lab-scale hollow fiber and flat sheet membranes. It is designed for tangential flow filtration and temperature controlled (37°C standard).

The easy-to-use software interface records flows, temperatures and pressures and allows the creation of individual test scripts. Whether you want to perform tests at constant crossflows, TMP or flux, our dialysis pilot has you covered.

The system is highly customizeable and can for example be designed to allow for testing of the filters integrity by applying an air pressure on the membrane or includes a in-line UV-VIS cell to measure for example concentrations of Creatinine or vitamin B-12.

Optional

- In-line UV-VIS measurement

- Membrane integrity testing with compressed air

- Customized flow and pressure ranges

SPECIFICATIONS

Permselectivity pilot

The Convergence Inspector Permselectivity pilot system is ideal for quality control and R&D on electrodialysis membranes. The system comes with a cell equipped with conductivity sensors. Based on the potential measurement and calculation of the expected potential the permselectivity can be calculated.

The membrane is in contact with two circulating electrolyte solutions. Ions with the same charge as the membrane (co-ions) are retained while ions of opposite charge (counter-ions) can pass through the membrane. The permselectivity of a membrane describes the charge selectivity of an ion-exchange membrane.

The user-friendly software interface records flows, temperatures and conductivity. Thus the permselectivity and trans-membrane pressure can directly calculated in the software. The software interface also allows the creation of individual test scripts. Whether you want to perform permeability tests with several different flux or temperature steps, the Permselectivity Inspector has you covered.

The system is highly customizeable and can for example be designed to include additional sensors, in-line heating and cooling. For quick quality testing a membrane module with a closing system can be included allowing the user to very quickly replace the tested membrane and increase the throughput.

Optional

- Cell closing system

- Customized flat sheet membrane modules

- Customized flow-, temperature- and pressure range (higher or lower)

- Heating or cooling system (includes heat exchangers and heating/cooling bath)

- Pressure control of electrolyte solutions

- Feed vessels (can also be heated or insulated)

SPECIFICATIONS

- Feed flow range: 12 – 60 L/h

- Feed flow accuracy: < 1 %

- Pressure range: 0,5 – 1,5 barg

- Pressure accuracy: < 0,1 %

- Temperature range: 0 – 60°C (higher temperatures optional)

- Dimensions: 70 x 26 x 38 cm

Ultrafiltration pilot / Microfiltration pilot

The Convergence Inspectors Microfiltration (MF) and Ultrafiltration (UF) pilot systems are ideal for quick studies on the performance of micro- and ultrafiltration membranes. With the Convergence Inspector the user can perform filtration tests, retention tests, fouling studies and cleaning and backwashing studies.

The lab-scale system is available in a standard or custom version and as a rental.

The user-friendly software interface records flows, temperatures and pressures. It allows the creation of individual test scripts: whether you want to perform simple filtration tests with several different pressure steps, flux stepping or simulate real life operating conditions with cleaning and backwashing steps, the Convergence Inspector MF/UF has you covered.

The system comes by default with a RX300 membrane kit and allows you to attach all kinds of hollow fiber and flatsheet membranes.

Optional

- In-line pH and conductivity measurement

- Customized flat sheet membrane modules

- Customized flow- and pressure range (higher or lower)

- High-end upgrade: includes gear pumps and coriolis flowmeters, the most accurate and fluid independent flowmeters on the market

SPECIFICATIONS

- Feed flow range: 1 – 20 L/h @ 6 bar max

- Backwash flow range: 1 – 20 L/h @ 6 bar max

- Permeate flow range: 0,2 – 20 L/h

- Flow accuracy: < 1 %

- Pressure range: 0 – 6 bar

- Pressure accuracy: < 0,1 %

- Dimensions: 70 x 26 x 38 cm

Reverse Osmosis pilot / Nanofiltration pilot

The Convergence Inspector Nanofiltration (NF) and Reverse Osmosis (RO) pilot systems have been developed to quickly evaluate the performance of nano- and reverse osmosis membranes at pressures up to 69 bar. With the Convergence Inspector NF/RO the user can perform filtration tests, retention tests, fouling studies and cleaning and backwashing studies.

The user-friendly software interface records flows and pressures and allows the creation of individual test scripts: whether you want to perform simple filtration tests with several different pressure or flux steps or membrane aging studies, the Convergence Inspector NF/RO has you covered. The system allows you to attach all kinds of flatsheet or spiral wound membranes and thus makes it extremely flexible.

The system is highly customizeable and can for example be designed to support pressures up to 125 bar, include additional sensors, allow backwashing studies or heating of the feed fluid and has many more options available.

Optional

- Backwash/cleaning system (up to 50L/h @ 6 bar max)

- In-line temperature, pH and conductivity measurement

- Customized flat sheet membrane modules

- Customized flow- and pressure range (higher or lower)

- High-end upgrade: includes coriolis flowmeters, the most accurate and fluid independent flowmeters on the market

- Feed tanks (different sizes available)

- Upgrade to chemical resistant Hastelloy/Duplex components

- Heating system (includes heat exchangers and heating bath)

SPECIFICATIONS

- Feed flow range: 15 – 400 L/h

- Feed flow accuracy: < 2 %

- Permeate flow range: 30 g/h – 30 kg/h

- Permeate flow accuracy: < 0,2 %

- Pressure range: 0 – 69 bar (up to 125 bar optional)

- Pressure accuracy: < 0,1 %

- Temperature range: 0 – 70°C (up to 130°C optional)

- Dimensions: 93 x 50 x 101 cm

Clean Water Flux pilot

The Convergence Clean Water Flux (CWF) pilot system was developed to quickly measure water permeability through membranes at reproducible temperature and pressure. The CWF is used to quantify the permeability of microfiltration and ultrafiltration membranes. It is defined as the volumetric flow through a certain membrane area at a certain pressure. It can be used for example to quantify membrane performance before and after membrane fouling took place.

Before testing takes place a crossflow flush makes sure that no air bubbles are present on the membrane and complete wetting took place. Afterwards the system will provide a flow through the membrane at a constant pressure. The permeate flowrate is monitored using a high precision balance.

The system comes with an A7 flat sheet membrane module (membrane size: 50 x 80 mm), but fits all kinds of hollow fiber and flat sheet modules provided by the end user.

With the integrated touch screen the user can easily set up his own experiments.

Optional

- Different flow and pressure ranges

- High precision flowmeter

- Flat cell closing system for fast replacement of tested membrane

- Several membrane modules

SPECIFICATIONS

- Feed flow range: 8 – 45 L/h

- Pressure range: 0,1 – 16 bar

- Pressure accuracy: < 0,1 %

- Temperature range: 0 – 60°C

- Dimensions: 40 x 21 x 29 cm

Membrane Fouling Simulator

The Convergence Membrane Fouling Simulator (MFS) was developed to quickly evaluate biofouling growth on RO membranes. The unit comes with a small cell and spacer for RO membranes. The system measures the pressure drop over the membrane over time at constant flow which will increase over the span of the experiment as biofouling growth constrics the flow path. The MFS is an easy and reliable method to compare and evaluate the biofouling potential of different feeds and membrane/spacer configurations.

With the integrated touch screen the user can easily set up his own experiments. The system runs at constant flows and pressures and is with equipped with a magnetic flowmeter. It can also be used to perform dead-end filtration experiments.

Optional

Higher feed pressure up to 6 bar

SPECIFICATIONS

- Feed flow range: 7 – 35 L/h

- Feed flow accuracy: < 1 %

- Pressure range: 0,1 – 4 bar pressure drop over the membrane

- Pressure accuracy: < 0,5 %

- Temperature range: 0 – 60°C

- Membrane size: 20 x 4 cm

- Dimensions: 40 x 21 x 29 cm

Bubble Point Tester

The Convergence Inspector Bubble Point (BP) tester automatically determines the BP and mean flow pore size of membranes and filters according to the ISO4003 and ASTM F316-03 standards. The unit automatically wets the inserted sample and determines the bubble point by applying a pressure slope on the filter. When air breakthrough occurs a pressure drop and increase in gas flow is detected and the measurement is stopped.

The easy-to-use touchscreen interface allows you to quickly set up automated experiments. The system is ideal for quality control and characterization of membranes.

The system is highly customizeable and can for example be designed to support several filter holders, house a built-in air compressor if pressurized air is not available or inlcude a liquid flowmeter to perform experiments determining the clean water flux.

Optional

- Customized flow- and pressure range (higher or lower)

- Built-in air compressor

- Customized fittings for user-defined filters

- Liquid flowmeter

SPECIFICATIONS

- Feed flow range: 2 – 100 mL/min

- Feed flow accuracy: < 0,2 % RD; < 1 % FS

- Pressure range: 0 – 6 bar

- Pressure accuracy: < 0,1 %

- Temperature accuracy: < 0,2 %

- Dimensions: 40 x 21 x 29 cm

- Wetting liquids: Water, 95 % Ethanol

Silt Density Index/Modified Fouling Index

The world-wide used ASTM standardized SDI (Silt Density Index) is a simple and cheap test to determine the fouling potential of water. Convergence Industry achieved to develop the first available portable and fully automatic SDI/MFI analyser for doing both SDI as wel as MFI (Modified Fouling Index) experiments.

SDI: Silt Density Index

To determine the rate at which particulate and colloid matter will foul membranes, the widely accepted method Silt Density Index (SDI, ASTM D4189) is used. Many (membrane) manufacturers have adopted this parameter and use it amongst other chemical/physical parameters as basis for their guarantee conditions.

The simple test compromises a short filtration cycle on a 0.45 um microfiltration (MF) membrane resulting in a indexed number.

A drawback of the SDI test is the fact that it is difficult to obtain a reproducible and accurate SDI value. Due to this there are often discussions on obtained SDI results. The most important known sources of error are:

- Variable microfiltration (MF) membrane properties

- Varying testing conditions

- Artifact causing parameters such as air bubbles

Therefore, it is recommended:

- To use a standardized membrane filters having uniform and constant properties

- To correct the SDI for temperature and membrane resistance

- To use a very accurate equipment

- To avoid the artifacts such as the effect of the bubbles, filter holder and operation errors

MFI : Modified Fouling Index

The Modified Fouling Index (MFI) is a measure for the fouling capacity of water on (mostly) membrane reactors. The MFI (0.45) has been developed to overcome the main deficiencies of SDI. The advantages of MFI are:

- Accurate measurement to predict feed- and driving pressure

- Temperature corrected

- Linear correlated with colloidal/suspended matter

- Fouling potential of particles <0.45 um is measured

- Applicable for highly fouled feed water

- Not dependent on test membrane permeability

- Applicable for Ultrafiltration (UF) permeate (feed to Reverse Osmosis (RO))

The obtained MFI value is corrected for temperature and pressure and shows a linear relation with colloidal suspended matter concentration.

Convergence Inspector SDI-MFI

The Convergence Inspector SDI Analyzer / MFI Analyzer is a test device that has been designed not only to consider the MFI (0.45) advantages, but also to minimize, if not eliminate, human errors. Due to the software installed the system is capable of measuring the following parameters in one test: SDI5, SDI10, SDI15, SDIv, SDI+ and MFI.

Specifications Filter Cartridge:

- Mean pore size: 0.45 um

- Diameter: 25 mm, flat

- Thickness: 115 – 180 um

Material:

- Pure water flow: 25 – 50s per 500 ml

- Pressure: 91.4 – 94.7 kPa

- Bubble point: 179 – 248 kPa

SPECIFICATIONS

- Dimensions: 30 x 25 x 18 cm

- Weight: 9,5 KG

- Data: USB 2.0

- Interface: HMI colour touchscreen

- Pump capacity: 10 – 300 ml/min

- Measuring range SDI: 0-6

- Measuring range MFI: 0-12

Electrodialysis pilot

The Convergence Inspector Electrodialysis (ED) pilot system is an ideal lab-scale solution for R&D or quality control testing on ED membranes. Convergence offers two types of systems: Electrodialysis(reversal) (ED(R)) and Reverse Electrodialysis (RED).

By default the unit consists of three circulating loops of fluid; the concentrate, diluate and electrolyte. If requested the system can also be fitted to operate three or four chamber ED cells. It is also equipped with a reversible power source for ED(R) testing or a potentionstat for RED measurements. In-line conductivity sensors allow live measurement of retention and scales allow the user to monitor the liquid flux across the membrane. The system can be customized to include in-line pH and temperature measurement.

The user-friendly software interface records flows, conductivities, current, voltage and pressures and allows the creation of individual test scripts. You can for example easily create experiments at constant voltages or currents and also include recurring EDR steps to combat scaling. It also allows automatic calculation of permeability, retention, and other user defined calculations. The system allows you to attach all kinds of ED test cells and thus makes it extremely flexible.

Optional

- In-line pH measurement

- In-line temperature measurement

- Customized flow- and pressure range (higher or lower)

- ED cells and membranes

- Automated recovery control

- Heating system (includes heat exchangers and heating bath)

- Additional inlets for operation of three or four chamber ED cells

SPECIFICATIONS

- Feed flow range: 25 – 150 L/h

- Feed flow accuracy: < 2 %

- Pressure range: up to 2 bar

- Pressure accuracy: < 0,1 %

- Voltage range: 1 – 32 V

- Current range: 0 – 15 A

- Temperature range: up to 60°C (higher temperatures optional)

- Dimensions: 60 x 50 x 93 cm

Forward Osmosis pilot

The Convergence Inspector Forward Osmosis pilot system was developed to quickly evaluate the performance of forward osmosis membranes and processes. The unit includes an in-line chemical cleaning line that allows the user to perform cleaning studies, biofouling tests, fouling test, permeability tests and more. Furthermore, in-line conductivity sensors allow live measurement of retention.

The system can be customized to allow the user to perform Pressure Retarded Osmosis experiments. The system is designed with dual pumps; one for the feed solution and one for the draw solution. Thus flow and pressure of the feed and draw solution can be controlled separately.

The user-friendly software interface records flows, temperatures and pressures and allows the creation of individual test scripts. Whether you want to perform permeability tests with several different pressure or flux steps or simulate on-field operation with cleaning steps, the FO Inspector has you covered. It also allows automatic calculation of permeability, retention, TMP (trans-membrane pressure) and other user defined calculations. The system allows you to attach all kinds of flatsheet or spiral wound membranes and thus makes it extremely flexible.

The system is highly customizeable and can for example be designed to support pressures up to 69 bar, include additional sensors, in-line chemical dosing, in-line heating or automated recovery control and has many more options available.

Optional

- In-line pH measurement

- Customized flat sheet membrane modules

- Customized flow- and pressure range (higher or lower)

- In-line chemical dosing

- Upgrade to chemical resistant Hastelloy/Duplex components

- Heating system (includes heat exchangers and heating bath)

- Feed & bleed recovery control

- Pressure control of feed and draw solution

SPECIFICATIONS

- Feed flow range: 6 – 150 L/h

- Feed flow accuracy: < 1 %

- Pressure range: 0,5 – 1,5 barg

- Pressure accuracy: < 0,1 %

- Temperature range: 0 – 60°C (higher temperatures optional)

- Dimensions: 60 x 50 x 54 cm

Pressure Retarded Osmosis pilot

The Convergence Inspector Pressure Retarded Osmosis pilot system was developed to quickly evaluate the performance of forward osmosis (FO) membranes and processes. The unit includes an in-line chemical cleaning line that allows the user to perform cleaning studies, biofouling tests, fouling test, permeability tests and more. Furthermore, in-line conductivity sensors allow live measurement of retention. The system is designed with dual pumps; one for the feed solution and one for the draw solution. Thus flow and pressure of the feed and draw solution can be controlled separately.

The user-friendly software interface records flows, temperatures and pressures and allows the creation of individual test scripts. Whether you want to perform permeability tests with several different pressure or flux steps or simulate on-field operation with cleaning steps, the PRO Inspector has you covered. It also allows automatic calculation of permeability, retention, TMP (trans-membrane pressure) and other user defined calculations. The system allows you to attach all kinds of flatsheet or spiral wound membranes and thus makes it extremely flexible.

The system is highly customizeable and can for example be designed to support pressures up to 69 bar, include additional sensors, in-line chemical dosing, in-line heating or automated recovery control and has many more options available.

Optional

- In-line pH measurement

- Customized flat sheet membrane modules

- Customized flow- and pressure range (higher or lower)

- In-line chemical dosing

- Upgrade to chemical resistant Hastelloy/Duplex components

- Heating system (includes heat exchangers and heating bath)

- Feed & bleed recovery control

SPECIFICATIONS

- Feed flow range: 6 – 150 L/h

- Feed flow accuracy: < 1 %

- Pressure range: 0,5 – 6 barg

- Pressure accuracy: < 0,1 %

- Temperature range: 0 – 60°C (higher temperatures optional)

- Dimensions: 60 x 50 x 54 cm

Gas Permeation pilot system

In order to characterize gas separation membranes with single or mixed gases, Convergence developed a gas permeation system. The unit allows the user to create their own customized feed gas composition and perform experiments at user defined flowrates, pressures and temperatures. Thanks to an integrated permeate side vacuum pump, solution-diffusion experiments can be performed using a pressure increment method.

The gas separation system can be supplied with a Convergence test cell, hollow fiber module or you can fit your own. The system works with thin films and composite membranes (on a ceramic support)

The system is equipped with a heating system. Cooling options and evaporator systems for introducing humidity or VOC’s is available as a custom option. On request the system is available in a bench top model (gas permeation system) or as a industrial sized pilot for full scale modules (gas permeation pilot).

The userfriendly software interface records flows, temperatures and pressures and allows the creation of individual test scripts. It also allows automatic calculation of permeability, permeance , stagecut, TMP (trans-membrane pressure) and other user defined calculations. The system allows you to attach all kinds of flat sheet membranes, tubular or hollow fiber membranes and thus makes it extremely flexible. A 47mm flat sheet membrane module is included.

The system is highly customizeable and can for example be designed to support operation at up to 250°C or allow the introduction of vapors through controlled evaporation and mixing. Different sensoring options such as dew point detectors or an automated GC are also available.

Optional

- Hollow fiber module

- Customized flow-, temperature- and pressure range (higher or lower)

- Additional gas inlets for mixtures

- In-line controlled evaporator and mixer to create vapours

- Membrane oven

SPECIFICATIONS

- Feed flow range: 0,16 nmL/min – 25 nL/min

- Feed flow accuracy: < 0,5 % of reading + 0,1 % of FS

- Permeate flow range: 0,16 nmL/min – 25 nL/min

- Permeate flow accuracy: < 0,5 % of reading + 0,1 % of FS

- Pressure range: 2 – 100 bar

- Pressure accuracy: < 0,1 %

- Temperature range: 0 – 120°C (different temperature ranges optional)

- Dimensions: 70 x 26 x 38 cm

Gas Booster

When performing research with gases, researchers often are limited to the available pressures from lab wall outlets or available gas bottles. Convergence developed a Gas Booster to increase pressure of the inlet gas up to 345 bar. The system can be used to almost completely empty gas bottles, saving the environment and money!

The system is run by an air driven pump and can boost gases to a user defined setpoint. When switching to a different gas the system will perform an automatic flushing step with an inert gas. Hardware and software side precautions ensure that hazardous situations are avoided.

Optional

- Other gases (e.g. H2, CH4)

- Higher pressure ratings

- Gas sensors to detect leaks

- Booster combined with mixing station for making mixtures

SPECIFICATIONS

- Inlet pressure: 1 – 80 barg

- Pressure output: 4 – 80 barg (up to 345 bar on request)

- Flow range*: 10 n L/min

- Gases: O2, CO2, N2, Air, He, Ar

*Sufficient driving air pressure must be available. Available air pressure also determines max boosting ratio.

Check www.con-vergence.com for the complete product portfolio.